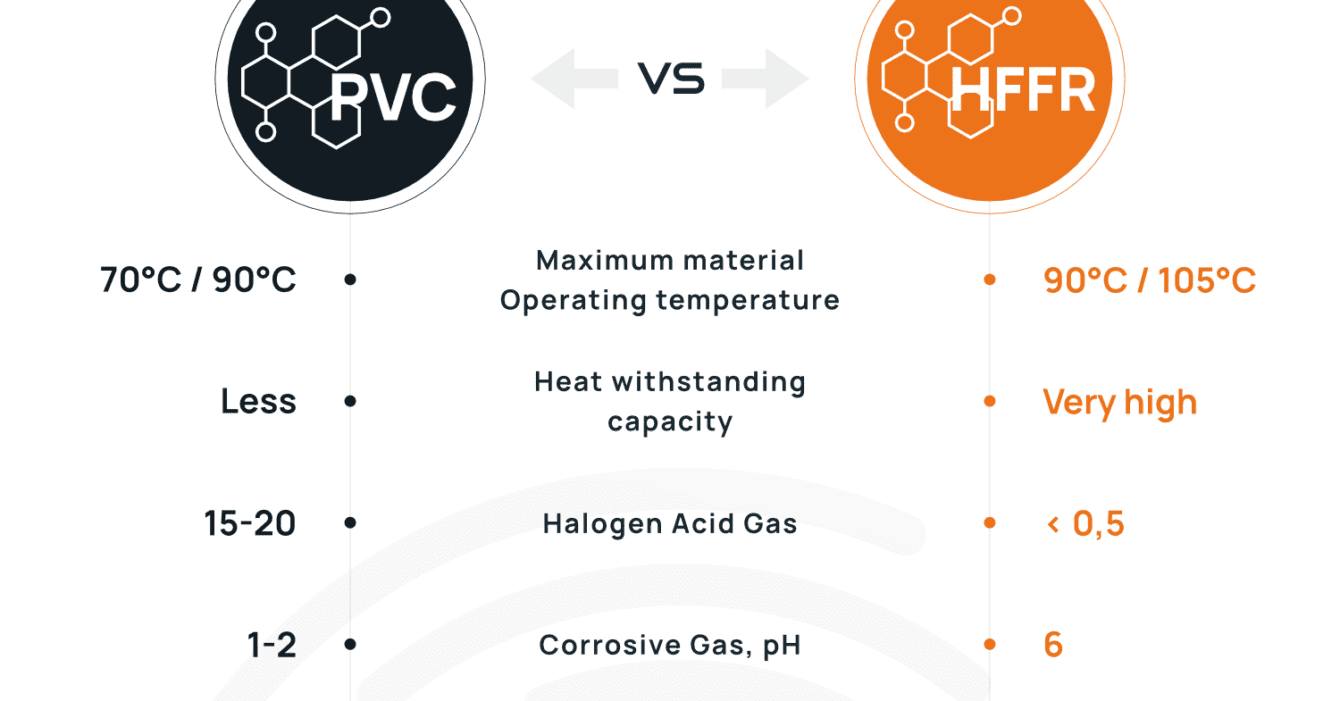

In the world of cable applications, two materials often come into discussion: Polyvinyl Chloride (PVC) and Halogen Free Flame Retardant (HFFR). Let’s delve into the key differences and why one might be chosen over the other. ⚖

🔹 PVC: A traditional choice, PVC has been widely used in industrial Low Voltage Cable and Building Wire. However, it has some drawbacks. In case of fire, PVC generates dark smoke, toxic and corrosive gas. In 2019, 90% of fire accidents were caused by electricity, and it’s noteworthy that most of the buildings use wires which are PVC cables, containing chlorine which make the buildings more susceptible to fire outbreaks.

🔹 HFFR: Over the last decade, HFFR materials have increasingly replaced PVC due to environmental and safety reasons. HFFR materials do not emit toxic gases or dark smoke when exposed to fire, making them a safer alternative. HFFR materials are increasingly being used in wire and cable applications due to their safety and environmental benefits. The industry is looking to improve the flame retardation, mechanical performance, and processability of HFFR compounds. With the broad portfolio of performance PE polymers, HFFR compounders now have the opportunity to optimize performance across these requirements. HFFR materials include plastics such as silicone rubber, polyurethane, polyethylene, polyamide, polypropylene, thermoplastic elastomers (TPE), or ethylene propylene diene rubber. They do not contain any heavy metal-based stabilizers or softeners, and the additives for flame protection are environmentally safe. While HFFR materials have higher raw material costs and can be more difficult to process, the difference in cable cost between PVC and HFFR becomes negligible when considering the high price of copper, the most significant element on total cable costs.

♻ In conclusion, while PVC has its place, the shift towards HFFR is evident due to its superior safety and environmental benefits. As we continue to innovate and develop new materials, the focus remains on creating safer, more sustainable solutions for our industry.

📩 In response to the changing needs of the market, SZEPLAST will start producing its own HFFR granules this year. For more information, please contact our colleagues!

🎁 Also, don’t forget to follow our page for more insightful content! Plus, in December, we’ll be giving away a special gift package to 5 lucky new followers of 2024! Don’t miss out!